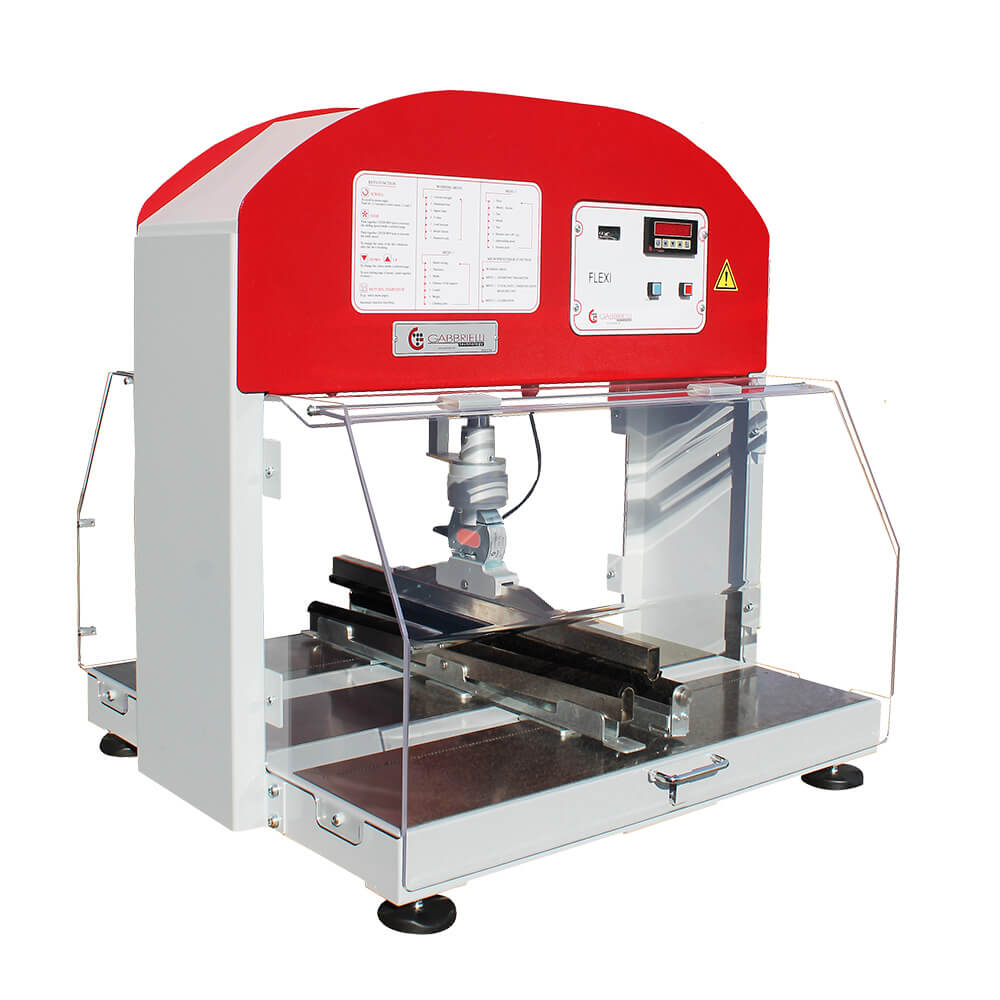

热门产品

成功案例

产品优势

-

货期短

01

货期短

-

速度快

02

速度快

-

有售后

03

有售后

-

高质量

04

高质量

关于我们

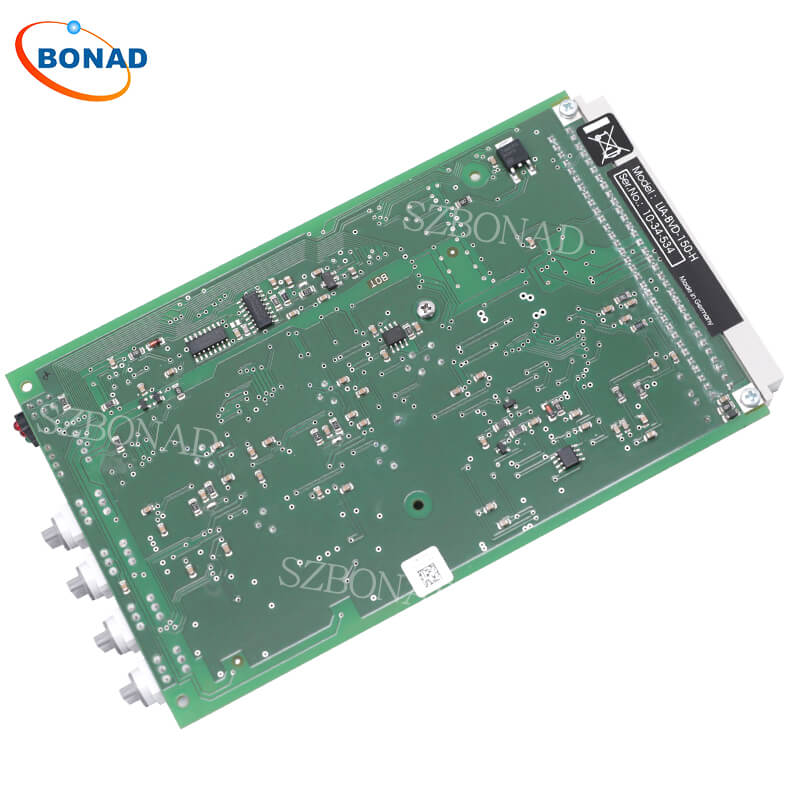

深圳市博纳德精密仪器有限公司是一家高速发展的重品质、创新型公司。公司一贯重视科学研究、技术开发及人才培养,是集仪器研发、生产、技术支持与服务于一体的“深圳市高新技术企业及国家高新技术企业”,属于国家重点支持的检测仪器领域的企业。博纳德公司沿革自深圳市奥创科技有限公司,后发展为独立法人的公司。经过多年的发展与完善,已在德国、香港设立分公司。目前产品远销欧美,并在欧美市场建立了自已的品牌,凭借强大的研...

read more 新闻中心

0708

DIN51130标准板热烈祝贺我司与德国知名标准测试板厂商合

DIN51130标准测试板,DIN51130倾角测试仪,DIN51130地板测试仪热烈祝贺我司与德国知名标准测试板厂商合作成功!如需详细资料欢迎来电垂询。

Read More 0708

热烈祝贺深圳市博纳德精密仪器有限公司取得英国MUNRO在中国

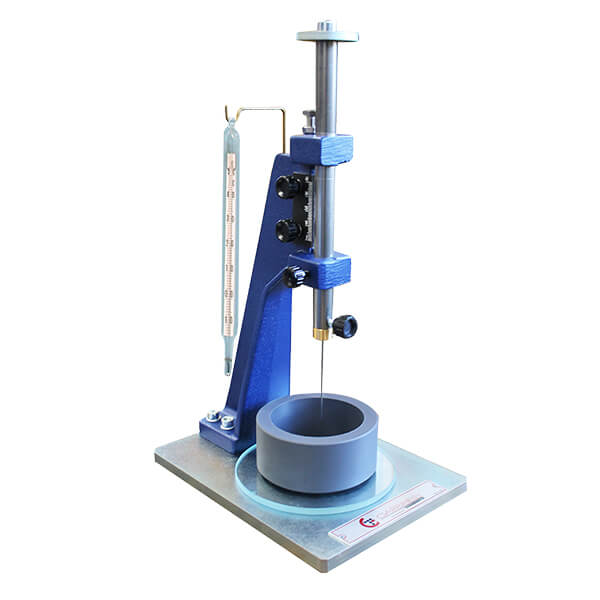

摆式仪是摆式磨擦系数测定仪的简称,是由英国原道路和运输研究所(TRRL)发明的。本仪器用来测定沥青路面、地板、磁砖其他材料试件的抗滑值,用以评定路面或材料试...

Read More 0708

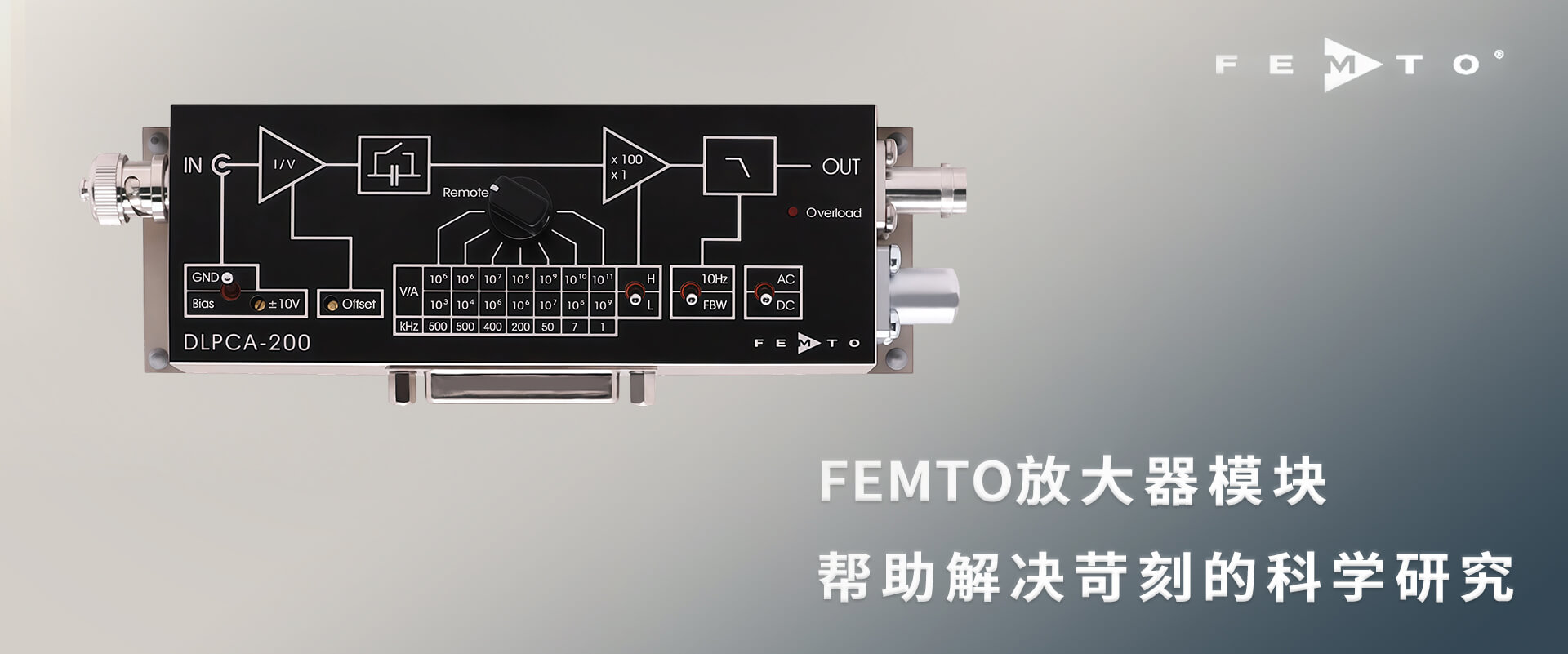

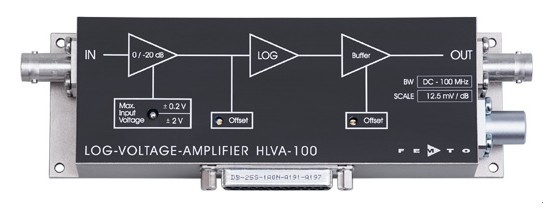

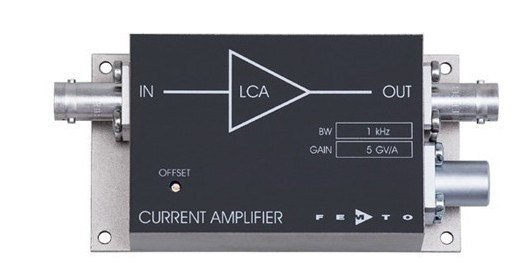

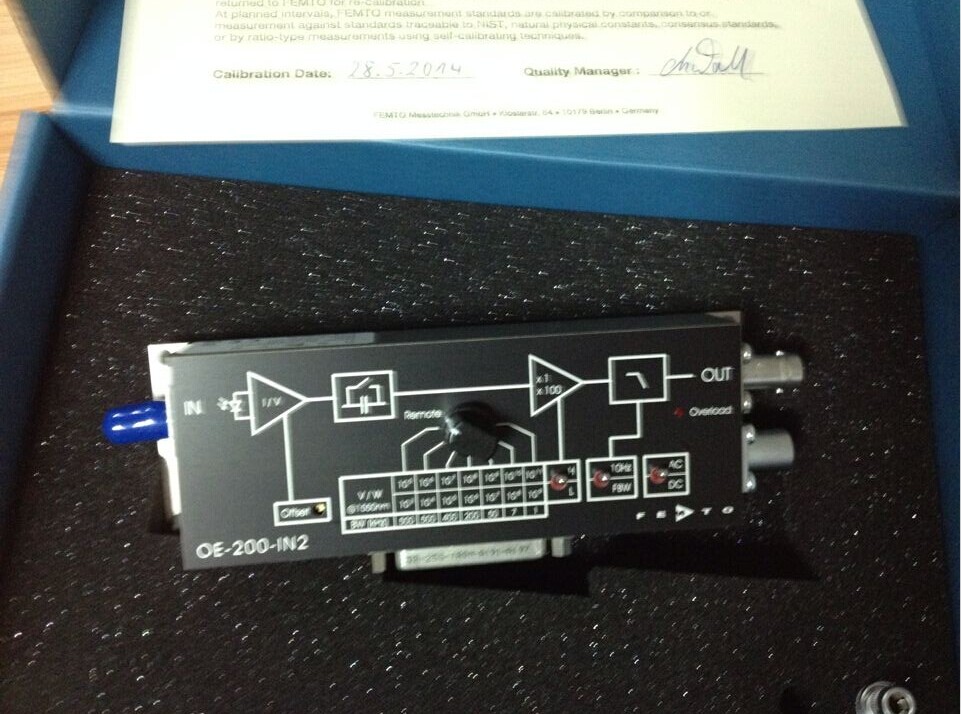

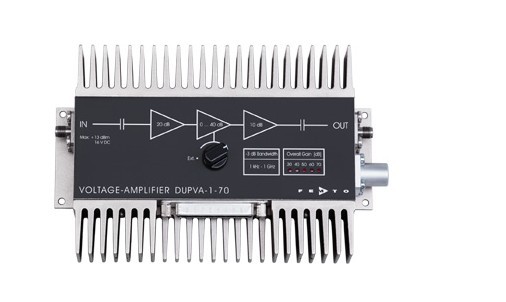

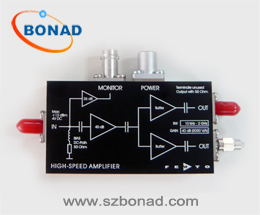

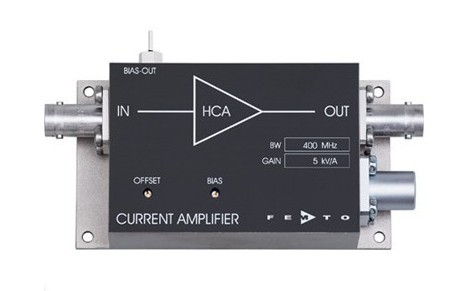

热烈祝贺博纳德取得德国FEMTO公司授权代理商资格

FEMTO公司的产品包括:电流放大器、电压放大器、GHZ宽带放大器、光接收器、锁相放大器以及一些定制的特殊放大器,具体型号如下:电流放大器DDPCA-300...

Read More 0708

光学斩波器的工作原理和使用场景

一、光学斩波器光学斩波器是一种定期中断光束的设备。有三种类型可供选择:变频旋转圆盘斩波器、固定频率音叉斩波器和光学快门。二、光学斩波器应用1、科学研究光学斩...

Read More