IEC 60335-2-2 clause 21.102 Figure 101 Current-Carrying Hoses Abrasion Resistance Tester

Product Overview:

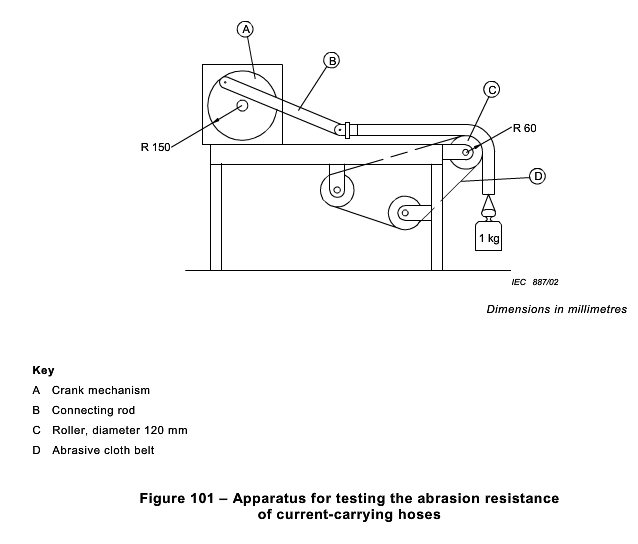

This current-carrying hoses abrasion resistance test equipment meets the standard of IEC60335-2-2, clause 21.102 figure 101. Suitable for verifying the vacuum cleaners or water-suction cleaning appliances's current-carrying hoses shall be resistant to abrasion.

Test Procesures (Extracted from IEC 60335-2-2 clause 21.102):

One end of the hose is attached to the connecting rod of the crank mechanism shown in Figure 101. The crank rotates at 30 revolutions per minute resulting in the end of the hose moving horizontally backwards and forwards over a distance of 300mm.

The hose is supported by a rotating smooth roller over which a belt of abrasive cloth moves at a speed of 0.1 m/min. The abrasive is corundum grit size P 100, as specified in ISO 6344-2. A mass of 1 kg is suspended from the other end of the hose, which is guided to avoid rotation.

In the lowest position, the mass has a maximum distance of 600 mm from the centre of the roller.

Test test is carried out for 100 revolutions of the crank.

After the test, basic insulation shall not be exposed and the electric strength test of clause 16.3 is carried out between the conductors connected together and the saline solution.

Main Paramters:

|

Feature

|

Description

|

|

Control Mode

|

PLC control with a touch screen human-machine interface for intelligent operation.

|

|

Test Station

|

Single station.

|

|

Frame Structure

|

Made from electrophoretic aluminum alloy with sprayed steel plate sealing; left-right structure, with control part on the left and test operation table on the right.

|

|

Tester Drive

|

Stepper reduction motor.

|

|

Crank Speed

|

Adjustable up to 30RPM via touch screen settings.

|

|

Moving Distance

|

300mm.

|

|

Moving Speed

|

Adjustable to 0.1m/mm via touch screen settings.

|

|

Test Belt

|

Complies with ISO/DIS6344 P100 size requirements.

|

|

Weight

|

1Kg.

|

|

Center Distance

|

The weight is positioned 600mm from the roller center.

|

|

Installation Position

|

The support plate should be pulled out during installation, with the weight placed on it and connected to the sample at exactly 600mm from the roller center.

|

|

Number of Tests

|

Configurable between 0-999 times via touch screen settings.

|

|

Equipment Power Supply

|

AC220V 50Hz.

|

Maintenance Notes

-

Cleaning: Keep the machine clean at all times to ensure optimal performance.

-

Rust Prevention: Regularly spray anti-rust oil on metal parts and standard interchangeable parts after use.

-

Lubrication: Periodically add lubricating oil to all rotating parts of the machine.

|